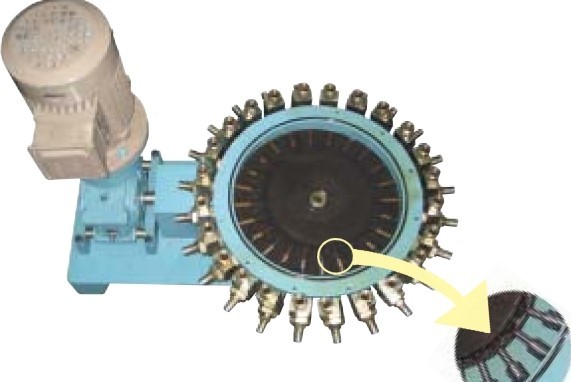

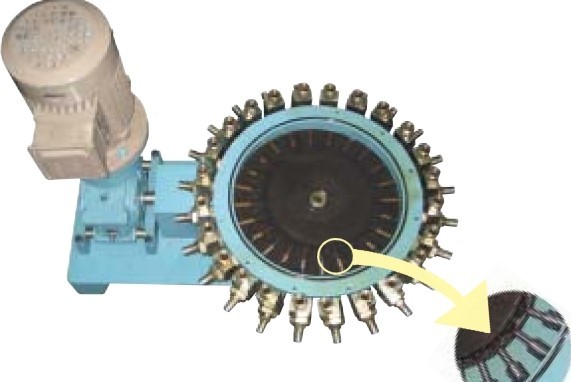

MULTILINE LUBRICATOR (also called Radial Lubricator or Multipoint Lubricator) is a user-friendly and cost-effective solution for centralized and automatic lubrication of a machine or an equipment having multiple lubrication points.

Multiline lubricator combines multiple pumps into a single entity sharing a common reservoir and common drive.

Working Principle - Multi Line Lubricator

-

A multi line lubricator consists of a number of small plunger type pumps called ‘pumping units’.

.jpeg)

-

These pumping units are located on the periphery of the lubricator housing and their pistons are connected to an eccentric cam. The rotation of the cam provides reciprocating motion to the pumping units.

-

The construction of the pumping unit ensures ‘positive suction stroke’. This is critical for accurate delivery in each stroke.

-

The cam is driven at a suitable rpm by an electric motor in conjunction with a gearbox.

-

The output per stroke of each pumping element can be adjusted independently.

-

The pressure developed by the pumping unit is sufficient to pump the lubricant and overcome the backpressure at lube point.

-

In grease lubricator, a stirrer is provided to eliminate air trapping and to ensure positive suction of grease.

-

For intermittent lubrication cycle timers are provided

ANSWRS by CENLUB SYSTEMS features and advantages -

-

Each pumping unit is actuated in each cycle and thus lubricates each line independently.

-

Output of each pumping unit can be adjusted independently. Output adjustment is achieved by just rotating adjusting screw

-

Lubricants of varying viscosity range can be used. Suitable for both oils (even heavy oils) and greases

-

Ensures low lubricant consumption (as low as 0.1cc/min) even for continuous duty operation

-

Automated operation is provided with the help of a timer to control lubricant cycle and lubricant consumption

-

Multiple drive options available for pump - motorized, manual, drive from the machine to be lubricated

-

High delivery pressures are obtained……. BAR

-

Multiline lubricator is an excellent solution for longer bearing-life and increased uptime of your machinery.

-

Robust construction makes multi line lubricator suitable for a variety of applications

-

Cenlub Systems multi line lubricator comes with a host of features to choose from.

Special Features

Positive suction - Interlocking of pumping unit with cam ensures a positive suction stroke. It ensures accurate deliveries in every stroke. It increases life, increases reliability and consistent performance compared to spring loaded pumping elements.

-

Oil resistant epoxy paint

-

Stirrer - Ensures proper suction of grease in each pumping element avoiding air-pocket formation

-

Simple design which is easy to maintain

Thanks & Regards

.jpeg)