Traditional manual lubrication methods, however, can be time-consuming, inconsistent, and prone to human error. Enter automatic

lubrication systems, a technological advancement that promises to revolutionize maintenance practices across various industries. This blog explores the latest advancements in automatic lubrication systems and their impact on efficiency, reliability, and cost savings.

What Are Automatic Lubrication Systems ALS ?

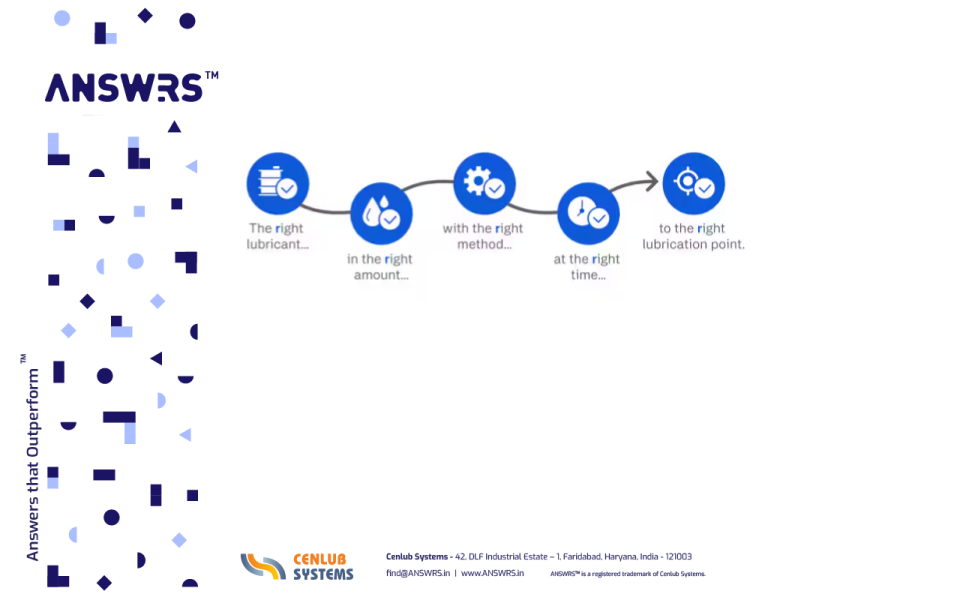

ALS, also known as centralized lubrication systems, are designed to deliver the right amount of lubricant to multiple points on a machine at regular intervals. These systems consist of a central pump or controller, lubricant reservoirs, and a network of distribution lines that deliver lubricant to the necessary components. The systems can be tailored to suit various machinery and operational requirements, making them versatile and widely applicable.

Recent Advancements in Automatic Lubrication Systems

1. Smart Lubrication Technology

One of the most significant advancements in

automatic lubrication systems is the integration of smart technology. Modern systems are equipped with sensors and IoT (Internet of Things) capabilities that monitor and adjust lubrication in real-time. These smart systems can detect changes in machinery conditions, such as temperature and vibration, and adjust lubrication schedules accordingly. This ensures optimal lubrication, reduces waste, and enhances machine performance.

2. Remote Monitoring and Control

Advancements in connectivity have enabled remote monitoring and control of lubrication systems. Maintenance personnel can now oversee and manage lubrication processes from a central location or even on the go using mobile devices. Remote access allows for quick adjustments, immediate response to issues, and detailed reporting, which improves maintenance efficiency and reduces downtime.

3. Precision Lubrication

Newer automatic lubrication systems offer precision lubrication, which ensures that the exact amount of lubricant is delivered to each point at the right time. This precision reduces over-lubrication and under-lubrication, both of which can cause significant issues in machinery performance and lifespan. By delivering the precise amount of lubricant, these systems help in conserving lubricant and reducing environmental impact.

4. Enhanced Durability and Reliability

Recent developments have focused on increasing the durability and reliability of automatic lubrication systems. Advanced materials and improved design have led to systems that are more resistant to harsh environmental conditions and mechanical wear. This increased reliability ensures consistent performance, reducing the risk of system failures and the associated maintenance costs.

5. Integration with Maintenance Management Systems

Automatic lubrication systems are increasingly being integrated with computerized maintenance management systems (CMMS). This integration allows for seamless data exchange, helping maintenance teams track lubrication schedules, monitor system performance, and predict maintenance needs. Such integration enhances overall maintenance strategies and supports proactive maintenance approaches.

Conclusion

The advancements in automatic lubrication systems represent a significant leap forward in industrial maintenance practices. From smart technology and remote monitoring to precision lubrication and enhanced reliability, these systems offer numerous benefits that improve efficiency, reduce costs, and extend equipment life. As industries continue to embrace automation and smart technologies, the adoption of advanced automatic lubrication systems is set to become increasingly widespread, driving further improvements in productivity and sustainability.

for any clarity, please discuss with us.

Thanks & Regards

Shweta Jindal - Marketing Manager